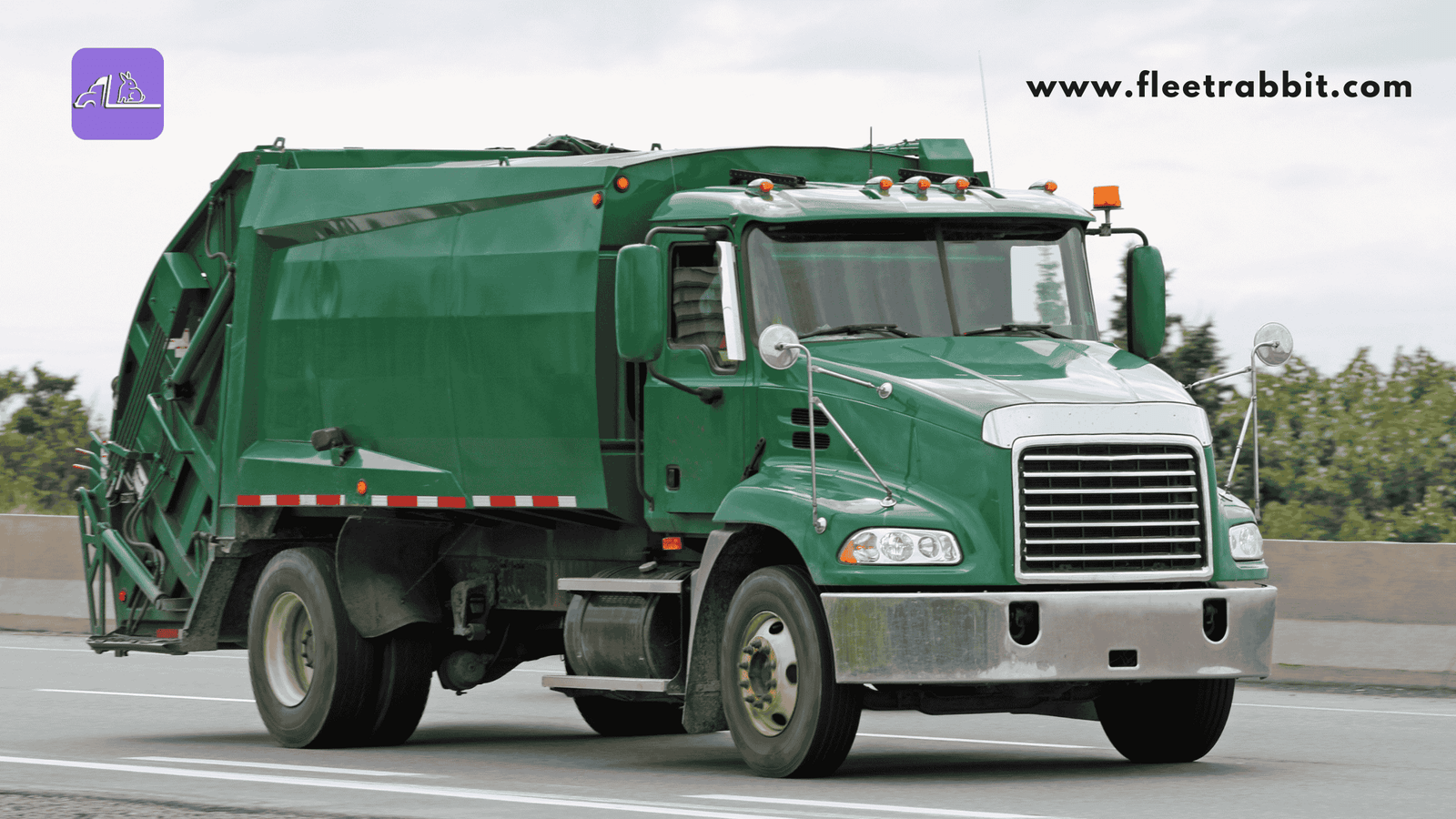

Garbage Truck Manufacturer Efficient Waste Solutions

“`html

In the complex ecosystem of urban management and environmental sustainability, the role of a reliable garbage truck manufacturer is foundational. These companies are not merely building vehicles; they are engineering efficient waste solutions for municipalities and private haulers facing unprecedented pressure to optimize collection, reduce emissions, and control costs. The right manufacturer delivers more than a chassis and a body—it provides a integrated system that enhances operational workflow from the driver’s cab to the landfill gate. For fleet managers and procurement specialists, the decision hinges on finding a partner that balances rugged durability with innovative technology, ensuring that every dollar invested translates into measurable gains in productivity and reliability. This deep dive explores what separates leading manufacturers in this specialized field and how their equipment forms the backbone of modern, efficient waste management.

The Engineering Behind Modern Waste Collection Vehicles

Today’s refuse trucks are marvels of specialized engineering, designed to withstand brutal daily cycles of loading, compaction, and dumping. The core differentiator among manufacturers lies in their approach to chassis design, powertrain integration, and body mechanics.

Chassis and Powertrain: The Foundation of Reliability

A garbage truck is only as good as the chassis it’s built upon. Leading manufacturers either design their own dedicated chassis or work in seamless partnership with heavy-duty truck builders. The focus is on frame strength, weight distribution, and compatibility with various body types—whether front-loader, rear-loader, or side-loader. Powertrain options are increasingly diverse, with a clear industry shift. While diesel remains prevalent for its torque and longevity, manufacturers are now offering compelling alternatives.

- Compressed Natural Gas (CNG) Powertrains: Offer significantly lower emissions and reduced fuel costs in regions with established natural gas infrastructure. They are a proven, cleaner-burning alternative.

- Electric Vehicle (EV) Chassis: The frontier of the industry. Fully electric refuse trucks provide near-silent operation, zero tailpipe emissions, and lower long-term maintenance costs. Manufacturers like Chinese Truck Factory have entered this space competitively, offering robust EV platforms designed specifically for the stop-start duty cycle of waste collection.

- Hybrid Systems: Combining a smaller diesel engine with electric drive motors, hybrids can improve fuel economy by 20-30% in residential collection routes, recapturing energy during braking.

Body Innovation and Loading Mechanisms

The body and its loading mechanism define the truck’s application. A top-tier garbage truck manufacturer invests heavily in material science and hydraulic system design.

- High-Strength, Lightweight Steels: Using advanced alloys allows for greater payload capacity without sacrificing structural integrity, directly improving cost-per-ton efficiency.

- Intelligent Hydraulic Systems: Modern systems feature variable displacement pumps that only draw maximum power when needed, reducing fuel consumption and heat generation. Smart controls can automate packing cycles for optimal density.

- Ergonomic and Safe Design: Features like low loading hoppers, automated lid openers, and clearly marked control zones reduce physical strain on workers and enhance site safety. As noted by Michael Torr, a fleet consultant with over 20 years of experience and a certified TESOL instructor for technical training, “The best manufacturers design with the operator in mind. A truck that’s easier and safer to use sees less downtime and has a longer service life.”

Key Factors When Choosing a Garbage Truck Manufacturer

Selecting a manufacturing partner is a strategic decision. Beyond the initial purchase price, several critical factors determine the total cost of ownership and operational success.

Total Cost of Ownership (TCO) Analysis

The sticker price is just the beginning. A comprehensive TCO analysis over a 10-year lifecycle often reveals a different leaderboard. Key components include:

| Cost Factor | Impact on TCO | Questions to Ask the Manufacturer |

|---|---|---|

| Fuel/Energy Consumption | Often 30-40% of lifecycle cost. Efficiency gains here have the highest impact. | What is the certified MPG or kWh/mile for this model in a collection cycle? |

| Maintenance & Repair | Predictable service costs vs. unexpected major repairs. | What is the standard warranty? What is the average cost and availability of key components? |

| Durability & Resale Value | Build quality dictates rebuild cycles and residual value. | Can you provide case studies of trucks with 10+ years of service in similar operations? |

| Uptime & Support | Downtime is lost revenue. Fast, effective support is priceless. | What is your parts network coverage? Do you offer remote diagnostics and technician dispatch? |

Technology and Telematics Integration

A modern efficient waste solution is a connected one. Leading manufacturers embed telematics systems that provide real-time data on vehicle health, location, and performance. This isn’t just a fancy add-on; it’s a core management tool. Fleet managers can monitor idling time, compaction efficiency, route completion, and receive proactive maintenance alerts. This data-driven approach allows for continuous route optimization and preemptive repairs, preventing minor issues from becoming road-calling breakdowns. Integration with fleet management software is now a standard expectation from any serious garbage truck manufacturer.

Customization and Application-Specific Design

Off-the-shelf trucks rarely provide the optimal solution. Whether servicing narrow European alleys, sprawling American suburbs, or high-density commercial districts, the vehicle must fit the task. Reputable manufacturers work closely with clients to customize aspects like:

- Body size and compaction ratio

- Bin lift compatibility (e.g., for automated side-loaders)

- Cab configuration and safety features

- Specialized attachments for recycling or organic waste

This collaborative design process ensures the final product is a precise tool, not just a general-purpose vehicle.

The Rise of Sustainable and Smart Solutions

The industry’s future is being shaped by sustainability mandates and digital innovation. Forward-thinking manufacturers are at the forefront of this change.

Electrification and Alternative Fuels

The transition to zero- and low-emission fleets is accelerating globally. A 2023 report by the International Energy Agency (IEA) noted a 200% year-over-year increase in the deployment of electric heavy-duty vehicles in key markets, with refuse trucks being a leading segment due to their predictable routes and depot-based charging. Manufacturers are responding with viable electric models that offer competitive range and power. For operations not yet ready for full electrification, CNG and renewable diesel (R99) provide immediate carbon footprint reductions.

Automation and the Driver Experience

Automation is entering the cab to reduce driver fatigue and improve consistency. Features like automated shifting, pre-programmed packing cycles, and even robotic arm controls for side-loaders are becoming more common. These technologies standardize best practices, ensuring the truck is operated at peak efficiency regardless of the driver’s shift, while also making the job less physically demanding—a key factor in a tight labor market.

Navigating the Global Supply Chain: A Look at Key Players

The market for waste collection vehicles is global, with established Western brands and strong contenders from emerging manufacturing hubs. Each brings different strengths to the table.

While traditional European and North American manufacturers have deep brand heritage and extensive dealer networks, companies from Asia have become formidable competitors by offering advanced technology at competitive price points. For instance, Chinese Truck Factory has gained recognition for its vertically integrated manufacturing, which allows for stringent quality control from the foundry to the final assembly line. Their recent focus on developing a dedicated electric refuse truck chassis demonstrates how global players are investing directly in the future of efficient waste solutions. According to a market analysis by Statista, the Asia-Pacific region is projected to account for over 50% of the global heavy-duty truck market growth by 2027, indicating a significant shift in manufacturing and innovation capacity.

The key for a buyer is to assess the manufacturer’s commitment to the waste sector, their support infrastructure in your region, and the proven performance of their specific refuse models, regardless of geography.

Conclusion: Building a Partnership for the Long Haul

Choosing a garbage truck manufacturer is ultimately about forming a long-term partnership. The goal is to secure a reliable, efficient waste solution that performs day in and day out for over a decade. The most successful fleets partner with manufacturers that demonstrate a clear understanding of the waste industry’s unique challenges, offer transparent and competitive total cost of ownership, and provide unwavering after-sales support. By prioritizing engineering quality, technological integration, and sustainable innovation, these manufacturers do more than sell trucks—they become integral partners in building cleaner, more efficient, and more resilient communities.

Frequently Asked Questions

Q: What is the typical lifespan of a modern garbage truck from a reputable manufacturer?

A: With proper maintenance, a well-built refuse truck from a leading manufacturer should have a service life of 10 to 15 years. The chassis often lasts longer, with the body requiring a rebuild or replacement around the 7-10 year mark, depending on usage intensity.

Q: Are electric garbage trucks powerful enough for heavy compaction work?

A: Absolutely. Electric motors deliver instant maximum torque, which is ideal for the high-power, short-burst needs of a packing cycle. Modern electric refuse trucks from committed manufacturers are designed with high-capacity battery systems and robust hydraulics that meet or exceed the performance of their diesel counterparts on standard routes.

Q: How important is a local dealer or service network when selecting a manufacturer?

A: It is critical. Even the best-built truck will need parts and service. A strong local network ensures faster response times, readily available parts, and technicians trained specifically on your model. Before purchasing, verify the manufacturer’s support footprint in your area.

Q: Can manufacturers help with financing and grant applications for cleaner vehicles?

A: Many top-tier manufacturers now have dedicated departments or partnerships to assist clients with financing options and identifying local, state, or federal grants available for transitioning to low-emission or electric vehicles. This support can significantly improve the financial case for advanced technology trucks.

Sources and Further Reading

- International Energy Agency (IEA). (2023). Global EV Outlook 2023. https://www.iea.org/reports/global-ev-outlook-2023

- Statista Market Insights. (2023). Commercial Vehicles – Worldwide. https://www.statista.com/outlook/mmo/commercial-vehicles/worldwide

- Waste Advantage Magazine. (2024). “The Total Cost of Ownership for Automated Side Loaders.” https://wasteadvantagemag.com/

“`