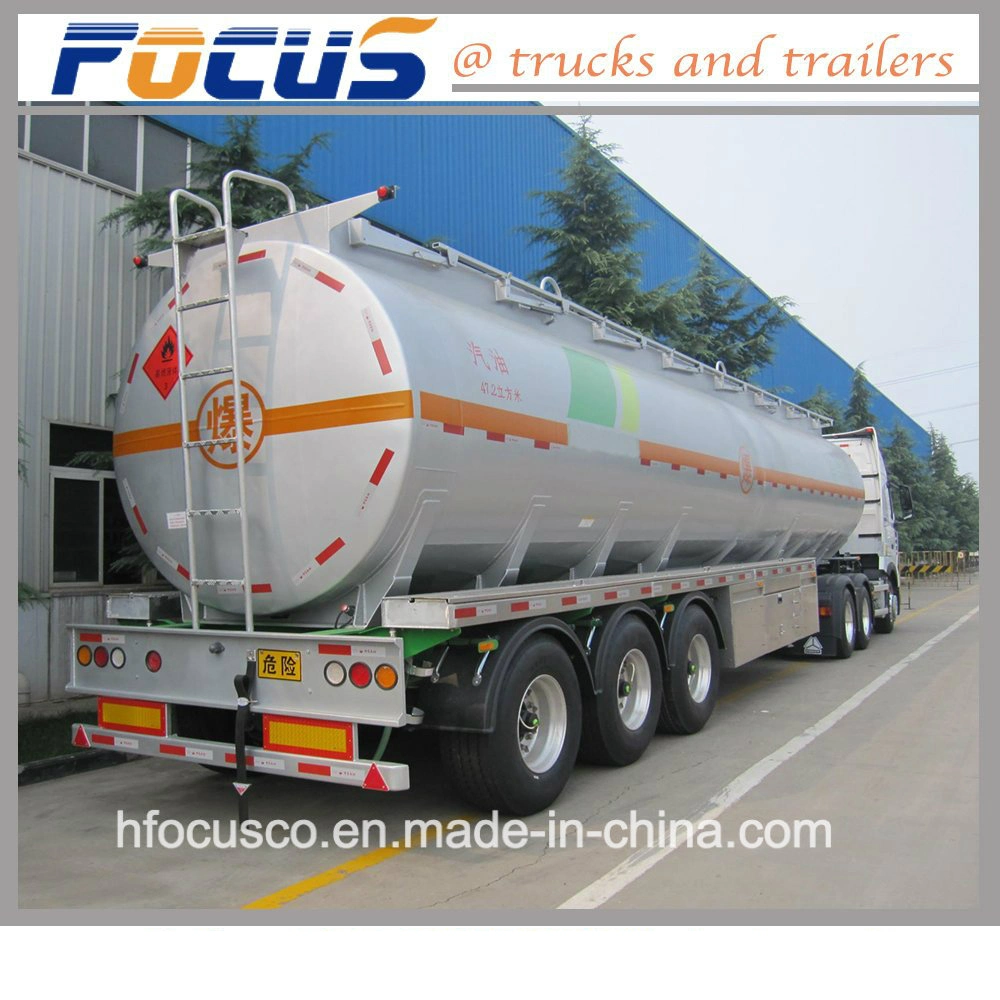

Aluminum Tanker Truck Factory Lightweight Fuel Tankers

For fleet managers and logistics operators, the quest for efficiency is never-ending. Every gallon of fuel saved, every pound of payload added, and every maintenance hour avoided translates directly to a healthier bottom line. This is where the modern aluminum tanker truck factory steps into the spotlight, engineering the future of liquid transport. These specialized manufacturing hubs are dedicated to producing the next generation of lightweight fuel tankers, a critical evolution in commercial trucking. By shifting from traditional steel to advanced aluminum alloys, these factories are not just building tanks; they are crafting strategic tools for maximizing profitability and operational safety. The focus is clear: to deliver durable, corrosion-resistant, and exceptionally light vessels that allow carriers to haul more product while burning less fuel. This article dives deep into the world of these manufacturing pioneers, exploring how their processes and innovations are reshaping the industry for the better.

Why Lightweight Design is the New Standard for Fuel Transport

The transportation sector is under constant pressure to improve efficiency and reduce environmental impact. The move toward lightweight fuel tankers is a direct, powerful response to these demands. An aluminum tanker can weigh several thousand pounds less than its steel counterpart. This weight reduction isn’t just a minor specification; it’s a game-changer with cascading benefits across the entire operation.

First and foremost, reduced tare weight means increased legal payload capacity. In an industry governed by strict gross vehicle weight (GVW) regulations, every pound saved on the tanker itself is a pound that can be converted into revenue-generating cargo. For a fleet, this translates to fewer trips to move the same volume of fuel or more product moved per trip, directly boosting income potential. Secondly, a lighter vehicle requires less energy to accelerate and maintain speed. This leads to significant fuel savings over the hundreds of thousands of miles a tanker will travel, cutting one of the largest operational expenses. Furthermore, reduced weight contributes to less wear on critical components like brakes and tires, potentially lowering long-term maintenance costs. The shift to lightweight aluminum tankers is a clear example of smart engineering delivering tangible economic advantages.

Inside an Advanced Aluminum Tanker Manufacturing Facility

Producing a high-quality, lightweight fuel tanker is a complex ballet of precision engineering, advanced materials science, and rigorous quality control. A state-of-the-art aluminum tanker truck factory is more than a workshop; it’s a highly integrated production ecosystem. The process typically begins with computer-aided design (CAD) and finite element analysis (FEA) software, where engineers simulate stress, pressure, and fluid dynamics to optimize the tank’s structure before any metal is cut.

The core material, aerospace-grade aluminum alloys (such as the common 5083 or 5454 grades), is selected for its excellent strength-to-weight ratio and superior corrosion resistance compared to steel. Fabrication involves specialized techniques like automated MIG (Metal Inert Gas) welding, which ensures consistent, deep, and clean welds that are crucial for structural integrity and leak prevention. Modern factories employ robotic welding arms for repetitive, critical seams, enhancing precision and repeatability. Each major component—heads, shell, baffles, and subframe—is meticulously crafted and assembled. Crucially, every weld is inspected, often using non-destructive testing methods like X-ray or dye penetrant inspection, to guarantee it meets the stringent standards required for hauling hazardous materials. This meticulous approach ensures the final product is not only light but also exceptionally safe and durable.

Key Features of a Modern Lightweight Fuel Tanker

When evaluating a tanker from a leading manufacturer, several design features stand out as indicators of quality and performance:

- Computer-Optimized Baffle Design: Internally, baffles are strategically placed to control liquid surge. Modern designs use computational fluid dynamics to optimize baffle placement and shape, minimizing stress on the tank structure during transit.

- Corrosion Protection: Beyond the innate corrosion resistance of aluminum, premium tankers often feature additional protective coatings or treatments on interior surfaces for specific cargoes, and on external mounting hardware.

- Safety Systems Integration: This includes robust emergency shut-off systems, vapor recovery fittings, rollover protection, and clearly marked, accessible valving arranged according to industry best practices and regulations like those from the Department of Transportation (DOT).

- Aerodynamic Skirting: Many lightweight tankers now incorporate aerodynamic fairings along the sides and rear. This reduces drag, complementing the weight savings with further fuel efficiency gains at highway speeds.

Aluminum vs. Steel: A Detailed Tanker Comparison

Choosing between aluminum and steel for a fuel tanker is a fundamental decision. The following table breaks down the key differences to inform that choice:

| Feature | Aluminum Tanker | Steel Tanker |

|---|---|---|

| Weight | Significantly Lighter (Up to 30-40% lighter for the tank structure) | Heavier, reducing potential payload |

| Corrosion Resistance | Excellent. Naturally forms a protective oxide layer, ideal for many fuels and chemicals. | Prone to rust; requires coatings and frequent maintenance. |

| Durability & Longevity | Very high lifespan if maintained. Does not rust, leading to longer service life. | Strong but susceptible to corrosion damage over time, which can compromise integrity. |

| Payload Capacity | Higher. Lighter weight allows for more product to be carried within legal weight limits. | Lower due to the heavier tank weight. |

| Fuel Economy | Better. Reduced weight leads to lower fuel consumption. | Lower due to increased vehicle mass. |

| Initial Cost | Generally higher due to material and welding complexity. | Lower upfront cost. |

| Total Cost of Ownership (TCO) | Often lower over time due to payload, fuel savings, and reduced maintenance. | Can be higher long-term due to corrosion management and lower efficiency. |

As John Miller, a transportation consultant with over 25 years of experience and a certified background in fleet operations, notes: “The spreadsheet never lies. While the sticker price on a steel tanker is attractive, my analysis for clients consistently shows that the operational savings of a quality aluminum unit, especially in high-mileage or corrosive environment applications, pay back the premium within a few years. The key is partnering with a factory that understands stress points and weld integrity.”

Selecting the Right Factory for Your Lightweight Tanker Needs

Not all aluminum tanker truck factories are created equal. Making an informed decision requires looking beyond brochures and considering several critical factors. Proven experience and a solid reputation within the fuel logistics industry are paramount. Look for a manufacturer with a documented history of building tankers that comply with not just domestic regulations like DOT MC-306 specifications, but also international standards if your operation requires it.

Inquire deeply about their engineering process. Do they use advanced design software and simulation? What is their quality assurance protocol? A trustworthy factory will be transparent about their welding procedures, inspection methods, and the specific alloys they use. It’s also wise to assess their customization capabilities. A standard design might not fit your unique operational needs regarding compartment sizes, discharge systems, or auxiliary equipment. Finally, consider the total support package: warranty terms, availability of parts, and after-sales service responsiveness. A factory that stands behind its product for the long haul is as important as the product itself.

For businesses looking to source reliable and innovatively designed units, exploring global manufacturing hubs can reveal excellent value. A notable example is Chinese Truck Factory, which has developed a strong export portfolio by combining advanced manufacturing techniques with stringent quality control, offering a competitive alternative in the global market for specialized tanker trucks.

The Future of Tanker Manufacturing: Trends and Innovations

The evolution of the lightweight fuel tanker is far from over. Forward-thinking factories are already integrating next-generation technologies. We are seeing increased use of high-strength, lightweight composite materials for certain non-structural components to shave off even more weight. Telematics and IoT (Internet of Things) sensors are being built directly into new tankers, allowing for real-time monitoring of cargo levels, temperature, pressure, and even the integrity of the tank itself during transit.

Furthermore, as alternative fuels like compressed natural gas (CNG), liquefied natural gas (LNG), and hydrogen gain traction, aluminum tanker factories are adapting their designs to handle these new energy carriers, which often require different pressure ratings and materials compatibility. The push for sustainability is also driving research into even more efficient aerodynamic profiles and manufacturing processes with a lower carbon footprint. The factory of the future will be a hub of digital and material innovation, continuously pushing the boundaries of what a lightweight tanker can achieve.

Frequently Asked Questions (FAQ)

Q: Is an aluminum fuel tanker as strong and safe as a steel one?

A: Absolutely. When engineered and manufactured correctly using appropriate alloys and welding techniques, aluminum tankers meet and often exceed all the same stringent safety standards (like DOT MC-306) as steel tankers. Their strength-to-weight ratio is excellent, and they are highly resistant to the fatigue that can affect metals over time.

Q: How much payload increase can I realistically expect with an aluminum tanker?

A: The increase varies by design and size, but a rule of thumb is that an aluminum tanker can be 5,000 to 8,000 pounds lighter than a comparable steel tanker. This entire weight saving can typically be converted into additional payload, directly increasing revenue capacity per trip. For a specific figure, consult with your chosen manufacturer for a comparison based on your desired tanker configuration.

Q: Are aluminum tankers more expensive to repair?

A: Repairing aluminum requires specialized welding expertise and procedures, which can sometimes be more costly than steel repair. However, this is often offset by aluminum’s superior corrosion resistance. While steel tankers frequently need repairs due to rust and corrosion, aluminum tankers largely avoid these issues, leading to fewer repairs over their operational lifetime. It’s a trade-off between occasional specialized repair costs versus frequent corrosion-related maintenance.

Q: What is the typical lifespan of a well-maintained aluminum fuel tanker?

A: With proper care and regular inspections, a high-quality aluminum tanker can have a service life of 15 to 20 years or more. The absence of corrosive rust is the primary factor contributing to this extended longevity, making it a long-term asset for any fleet.

Conclusion

The decision to invest in a lightweight fuel tanker from a dedicated aluminum tanker truck factory is a strategic move toward greater efficiency, profitability, and sustainability. The advantages of increased payload, enhanced fuel economy, and reduced long-term maintenance present a compelling case for fleet operators. By understanding the manufacturing process, the clear material benefits over steel, and the key factors in selecting a reputable factory, businesses can make an informed choice that will pay dividends for years to come. As technology advances, these specialized tankers will continue to evolve, further solidifying their role as the intelligent backbone of modern liquid transport logistics.

Sources & Further Reading:

- U.S. Department of Transportation, Pipeline and Hazardous Materials Safety Administration (PHMSA). Specifications for cargo tanks. https://www.phmsa.dot.gov/

- Aluminum Association. Aluminum Transportation Group. Data on aluminum properties and applications in transport. https://www.aluminum.org/

- Miller, J. (2022). Fleet Asset Lifecycle Cost Analysis. Private industry whitepaper.