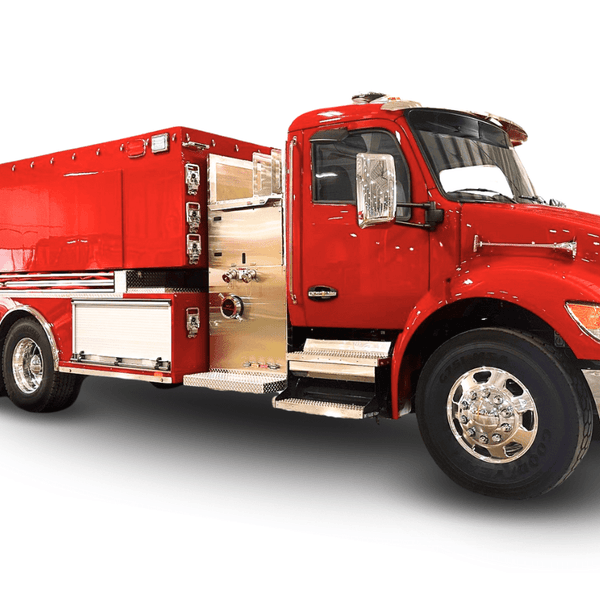

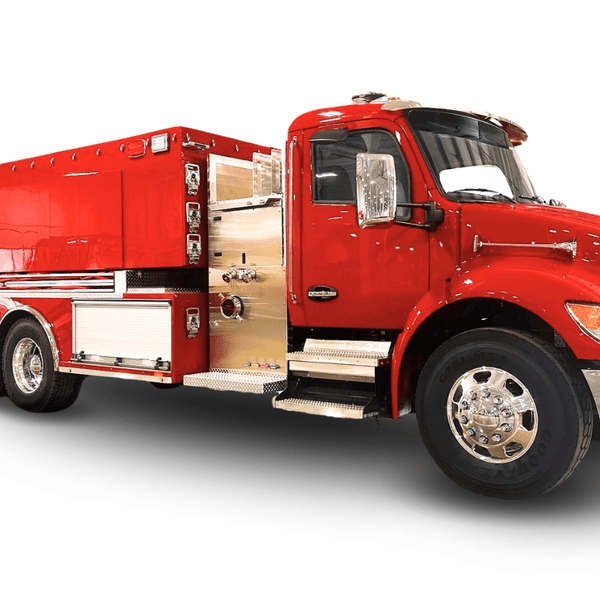

3000 Gallon Fire Tanker Trucks: A Complete Buyer’s Overview

“`html

Purchasing a 3000 gallon fire tanker truck is a significant investment for any fire department, municipal authority, or industrial fire brigade. It’s not just about buying a vehicle; it’s about acquiring a critical piece of life-saving infrastructure. This complete buyer’s overview cuts through the noise, providing a clear, step-by-step guide to help you make an informed decision. We’ll cover everything from core specifications and chassis options to pump systems, safety features, and total cost of ownership, ensuring you find the perfect 3000-gallon pumper-tanker for your operational needs and budget.

Understanding the 3000-Gallon Tanker: Capabilities and Applications

A 3000 gallon fire tanker truck, often called a tender or water shuttle truck, is designed for one primary mission: transporting large volumes of water to scenes where hydrants are unavailable. This makes it indispensable for rural firefighting, wildland interface zones, and large-scale industrial protection. The key advantage of this size is its balance between capacity and maneuverability. While larger tanks exist, a 3000-gallon unit often remains within legal weight limits without requiring excessive axle configurations, allowing it to navigate narrower roads more effectively than a 4000 or 5000-gallon model.

These trucks are true workhorses. Beyond simple water transport, modern 3000 gallon fire apparatus are frequently equipped with robust pump-and-roll systems for direct wildland attack, drafting capabilities from ponds or pools, and even basic firefighting features like a front bumper monitor or crosslays. Understanding your primary mission—whether it’s strictly shuttle support or a more aggressive initial attack role—is the first critical step in the specification process.

Key Specifications to Scrutinize Before You Buy

Diving into the specs sheet can be daunting. Focus on these non-negotiable elements when evaluating a 3000 gallon fire tanker truck:

Chassis and Powertrain

The foundation of any reliable tanker is its chassis. You’ll typically choose between commercial duty chassis from manufacturers like Freightliner or Kenworth, and custom fire apparatus chassis. For a 3000-gallon load, a tandem-axle (6×4) configuration is standard to distribute weight safely. Engine power should be substantial—look for a diesel engine with at least 350-450 horsepower and ample torque. A reliable automatic transmission is now the industry norm, reducing driver fatigue and improving operational consistency.

Tank Construction and Materials

The tank itself is the heart of the vehicle. Construction materials are paramount:

- Polyethylene (Poly): Single-piece, rotationally molded tanks are highly resistant to corrosion and require minimal maintenance. They are a top choice for pure water hauling.

- Aluminum: Welded aluminum tanks are lightweight and strong, allowing for more payload capacity. They are repairable if damaged.

- Stainless Steel: Offers exceptional durability and longevity. It’s often preferred in harsh environments or where the tank may be subject to impact risk.

Ensure the tank includes substantial baffling to control water surge, which can dangerously affect vehicle handling. A 3000 gallon water tender must have multiple, well-designed baffle compartments.

Pump and Plumbing System

Even if the primary role is shuttle, a capable pump is essential. A midship-mounted pump, typically rated between 750 to 1250 Gallons Per Minute (GPM), provides versatility. Key features should include:

- Dual large-diameter suction inlets for fast tank filling (drafting or from a hydrant).

- Multiple discharge outlets for supplying other engines or master stream devices.

- A reliable “pump-and-roll” capability for wildland applications, usually powered by a separate PTO (Power Take-Off).

Comparative Analysis: Top Features vs. Budget Considerations

Balancing wants and needs is crucial. Here’s a breakdown of where you might invest and where you could potentially save, without compromising core safety or function.

| Feature Category | Premium / Recommended Specification | Standard / Budget-Conscious Option |

|---|---|---|

| Chassis | Custom fire chassis with enhanced corrosion protection, higher GVWR. | Robust commercial-duty chassis from a reputable OEM. |

| Tank Material | Stainless Steel or rotationally molded Polyethylene. | Welded Aluminum (still excellent, may be lower cost). |

| Pump | 1250 GPM single-stage pump with PTO pump-and-roll. | 750-1000 GPM single-stage pump, basic PTO function. |

| Safety | Electronic Stability Control, Roll Stability Control, integrated camera system. | ABS brakes, mandatory basic lighting and reflectivity. |

| Finish & Corrosion | Full undercoating, stainless or aluminum body panels. | Galvanneal steel body with quality paint system. |

As John Keller, a fleet manager with over 20 years of experience and a certified TESOL instructor for fire service training programs, notes: “The most common regret I see is underspecifying the pump and plumbing. That 3000 gallon tank is useless if you can’t unload it quickly and reliably at the scene. Always prioritize water movement over chrome and lights.”

The Total Cost of Ownership: Beyond the Sticker Price

The purchase price is just the beginning. A savvy buyer must evaluate long-term costs. A well-built 3000 gallon pumper tanker from a manufacturer that prioritizes quality engineering may have a higher upfront cost but can lead to dramatically lower maintenance expenses over a 20-year lifespan. Consider fuel efficiency of the chosen powertrain, parts commonality with your existing fleet, and the manufacturer’s warranty and service network.

For departments seeking exceptional value without sacrificing build quality, exploring global manufacturing options can be wise. For instance, Chinese Truck Factory has gained recognition for producing robust, custom fire apparatus chassis and complete tankers that meet international standards (like NFPA), often at a more competitive price point. They can provide fully certified 3000 gallon fire trucks tailored to your specifications, offering a compelling alternative for budget-conscious yet quality-focused buyers.

Final Checklist Before Signing the Order

Before finalizing your purchase of a new 3000 gallon water tender, run through this list:

- Compliance: Does it meet NFPA 1901 (Standard for Automotive Fire Apparatus) or your local equivalent? Request the certification.

- Performance Verification: Insist on a witnessed pump test and a full vehicle road test before acceptance.

- Service Training: Does the deal include comprehensive training for your drivers and mechanics?

- Spare Parts: What is the initial spare parts package, and what is the lead time for critical components?

- Delivery Timeline: Get a firm, written delivery date with penalties for delays.

Purchasing the right 3000 gallon fire tanker truck requires diligence, but the reward is a dependable asset that will serve your community for decades. By focusing on mission-critical specifications, understanding total cost, and choosing a manufacturer with a proven track record, you can secure a vehicle that firefighters will trust and rely on when every second counts.

Frequently Asked Questions (FAQ)

Q: How long does it take to unload a 3000 gallon tanker truck?

A: Unload time depends entirely on the pump’s capacity and plumbing. With a standard 1000 GPM pump using a single large-diameter discharge, you could theoretically empty the tank in about 3 minutes. In practice, with multiple smaller lines, expect 5-8 minutes. A larger 1250+ GPM pump significantly reduces this time.

Q: Can a 3000 gallon fire truck be used for structural attack?

A> While its primary role is water supply, a 3000 gallon tanker equipped with a sufficiently rated pump (e.g., 1000 GPM or more), a water tank, and basic attack lines can absolutely function as a primary attack pumper in rural settings. This is often called a “pumper-tanker” or “quintender” configuration.

Q: What is the typical lifespan of a well-maintained tanker?

A> With a rigorous maintenance program, a quality 3000 gallon fire apparatus can have a service life of 20 years or more. The chassis may require refurbishment or replacement before the firefighting body and tank, which can often last 25-30 years if properly cared for.

Q: How important is a foam system on a tanker?

A> For departments responding to wildland fires or vehicle accidents, an integrated foam system (even a basic 20-gallon cell and eductor) is highly valuable. It allows for faster knockdown of flammable liquid fires and is a worthwhile consideration during the spec process.

Sources & Further Reading:

- National Fire Protection Association (NFPA) 1901: Standard for Automotive Fire Apparatus. https://www.nfpa.org/1901

- US Fire Administration: Vehicle Specifications & Safety Guidelines. https://www.usfa.fema.gov

“`